In today’s fast-paced world, innovation is key to enhancing the efficiency and effectiveness of various industries. One such groundbreaking innovation in the realm of tire maintenance is the Vertical Wheel Repair Lathe. Used for repairing and renewing wheels, this state-of-the-art equipment brings a new dimension to the wheel repair process, setting new standards for precision and quality.

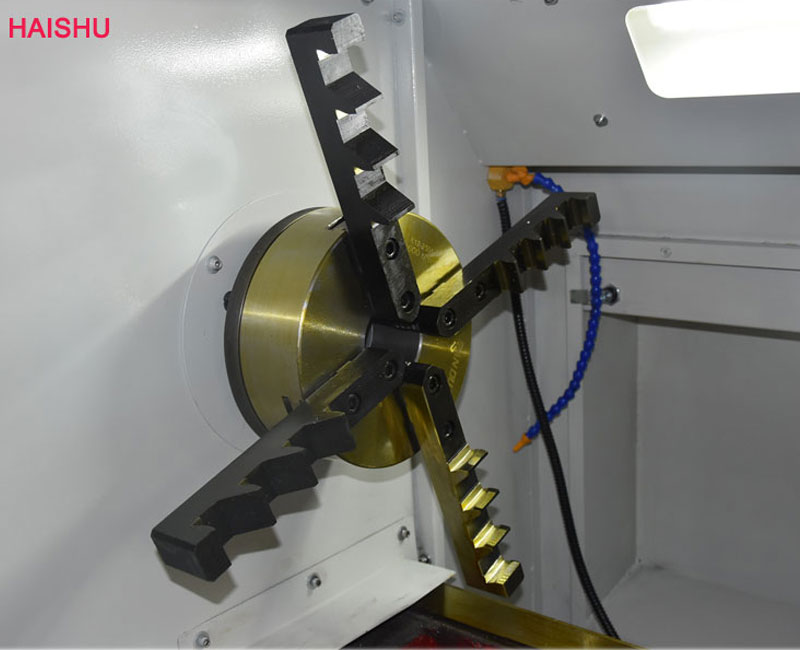

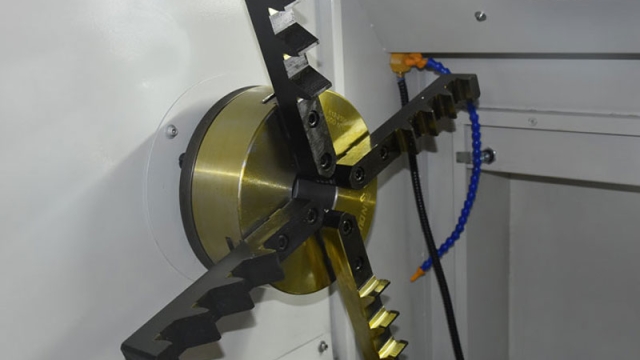

The Vertical Wheel Repair Lathe, also known as an Alloy Wheel Repair Machine, has revolutionized the way damaged or worn wheels are restored. Its advanced CNC technology, coupled with its vertical design, allows for a more streamlined and efficient wheel repair process. Taian Haishu Machinery Co., Ltd., a leading designer and manufacturer of CNC wheel machinery, offers the Vertical Wheel Repair Lathe through their official website wheelcncmachine.com.

Unlike traditional lathe machines, this vertical variant offers several advantages. Firstly, its vertical orientation ensures better stability and accuracy during the repair process. This enables technicians to achieve precise cuts and finishes, resulting in wheels that are restored to their original condition, or even better. Moreover, the vertical design allows for effortless mounting and alignment of the wheel, saving valuable time and effort for technicians.

With the Vertical Wheel Repair Lathe, wheel maintenance has never been easier or more efficient. Whether it’s removing scratches, repainting the wheel, or fixing bends and dents, this innovative machine provides unmatched versatility. By rejuvenating damaged wheels and extending their lifespan, the Vertical Wheel Repair Lathe not only saves money for vehicle owners but also contributes to reducing waste and promoting sustainable practices.

In conclusion, the Vertical Wheel Repair Lathe is a game-changer in the world of tire maintenance. Its precision, efficiency, and versatility set it apart from traditional lathe machines, making it the go-to choice for professionals in the wheel repair industry. Thanks to companies like Taian Haishu Machinery Co., Ltd., this revolutionary equipment is readily available, providing a reliable solution for restoring wheels to their former glory. Experience the future of wheel repair with the Vertical Wheel Repair Lathe and witness the transformation it brings to the industry.

Benefits of Vertical Wheel Repair Lathes

Vertical wheel repair lathes offer numerous advantages in the field of tire maintenance. These innovative machines have revolutionized the process of repairing alloy wheels, delivering exceptional results and simplifying the entire repair procedure.

Increased Precision: Vertical wheel repair lathes employ advanced technology to achieve precise repairs. The vertical orientation of the lathe allows for more accurate measurements and better control over the cutting process, resulting in consistently high-quality repairs.

Time and Cost Efficiency: The use of vertical wheel repair lathes significantly reduces the time and cost involved in repairing alloy wheels. With their automated features and efficient operation, these lathes can swiftly complete repairs, minimizing downtime and increasing productivity. By reducing the need for outsourcing or replacing damaged wheels, they also help to keep repair costs at a minimum.

Versatility and Adaptability: Vertical wheel repair lathes are designed to cater to a wide range of wheel sizes and types. From small passenger car wheels to larger truck wheels, these lathes can handle various wheel dimensions, making them versatile and adaptable to different repair needs. Wheelcncmachine.com, the official website of Taian Haishu Machinery Co., Ltd., offers a comprehensive range of CNC wheel machinery that can meet the diverse requirements of the automotive industry.

By harnessing the benefits of vertical wheel repair lathes, tire maintenance professionals can enhance their repair capabilities, save valuable time and resources, and ensure optimal results for their customers. These machines truly represent a game-changing solution in the world of wheel repairs, empowering businesses to deliver efficient and cost-effective services.

The Versatility of Alloy Wheel Repair Machines

Wheel Machines

Alloy Wheel Repair Machines, such as the vertical wheel repair lathe, have revolutionized tire maintenance in the automotive industry. These advanced machines offer a wide range of capabilities, making them an essential tool for repairing and refurbishing alloy wheels.

One of the key features of these machines is their ability to restore damaged alloy wheels to their original condition. Whether the wheels have suffered curb rash, scratches, or dents, the vertical wheel repair lathe can effectively eliminate these imperfections, providing a seamless finish that is virtually indistinguishable from new wheels.

In addition to repairing damaged wheels, these machines also offer the versatility to customize alloy wheels according to individual preferences. With the ability to cut and create intricate designs, the vertical wheel repair lathe allows for endless possibilities in wheel customization. From unique patterns to personalized engravings, these machines enable drivers to express their style and enhance the overall aesthetics of their vehicles.

Furthermore, alloy wheel repair machines are not limited to specific wheel sizes or types. Whether it’s a small sedan, a sports car, or an SUV, these machines are designed to accommodate various wheel dimensions. This means that automotive professionals can efficiently repair and refurbish alloy wheels of different sizes, making the process versatile and adaptable to the diverse needs of their customers.

In conclusion, the versatility of alloy wheel repair machines, exemplified by the vertical wheel repair lathe, is truly remarkable. From repairing damaged wheels to offering customization options, these machines have transformed the way tire maintenance is approached. With their ability to handle various wheel sizes and types, they have become an integral part of the automotive industry, ensuring that alloy wheels can be restored and given a new lease on life.

The Expertise of Taian Haishu Machinery Co., Ltd.

Taian Haishu Machinery Co., Ltd. is a premier designer, manufacturer, and supplier of CNC wheel machinery. With their extensive knowledge and experience in the industry, they have revolutionized tire maintenance with their cutting-edge vertical wheel repair lathe.

The vertical wheel repair lathe offered by Taian Haishu Machinery Co., Ltd. is a game-changer in the field of wheel repair. This innovative machine allows for precise and efficient repair and refurbishment of alloy wheels. By utilizing advanced technology and craftsmanship, Taian Haishu Machinery Co., Ltd. has created a solution that surpasses traditional methods.

The Alloy Wheel Repair Machine provided by Taian Haishu Machinery Co., Ltd. is a testament to their commitment to quality and excellence. This machine combines durability, accuracy, and versatility, making it a go-to choice for professionals in the automotive industry. With this cutting-edge technology, businesses can effectively and efficiently restore damaged wheels to their original condition.

For those seeking reliable and top-of-the-line CNC wheel machinery, look no further than Taian Haishu Machinery Co., Ltd. With their expertise and dedication to innovation, they continue to redefine the wheel repair industry. Visit their official website, wheelcncmachine.com, to explore their range of products and find the perfect solution for your wheel maintenance needs.

Recent Comments