Introducing the Ultimate Guide to Pallet Wrappers: Mastering Stretch Wrap Machines

Are you tired of spending countless hours manually wrapping pallets, only to have them shift and become unstable during transportation? Look no further! In this comprehensive guide, we will unveil the secrets to becoming a pallet wrapping expert. Whether you’re a seasoned warehouse manager or a novice to the world of logistics, our step-by-step instructions and insider tips will help you master the art of using stretch wrap machines effectively.

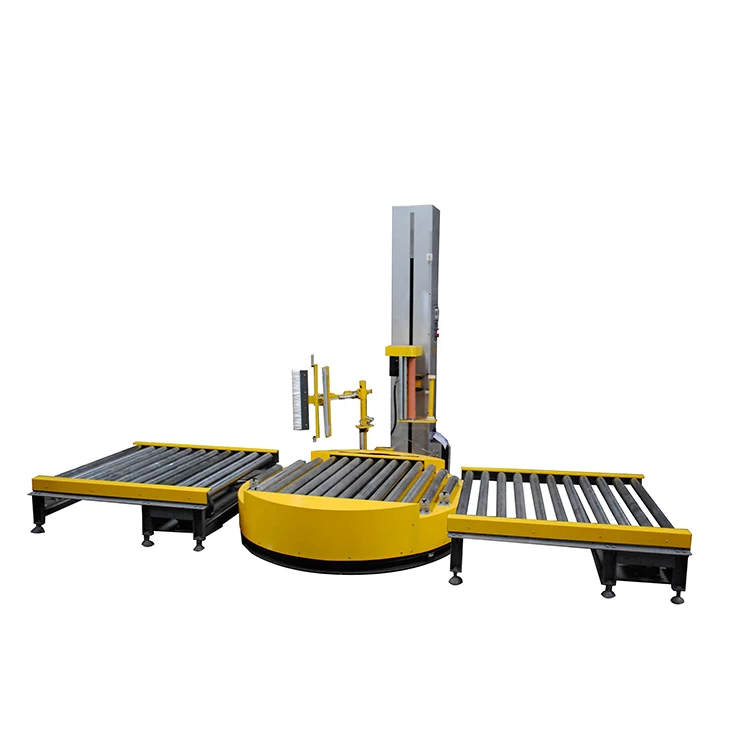

Pallet wrappers, also known as stretch wrap machines, have revolutionized the way pallets are secured for transportation. These intelligent devices take the hassle out of manual wrapping by automatically applying stretch film around the entire pallet load, ensuring it remains intact and secure during transit. With their ability to tightly bind the items together, pallet wrappers not only protect against damage but also provide stability, making your warehouse operations smoother and more efficient.

In this guide, we will explore the different types of pallet wrappers available in the market, from semi-automatic to fully automatic machines. We will discuss the key features to consider when selecting a pallet wrapping machine, such as film pre-stretch capabilities, turntable speeds, and weight capacity. Additionally, we will delve into the various stretch wrap film options, including gauge thickness and film tension, to help you choose the most suitable materials for your specific needs.

Stay tuned as we delve deeper into the intricacies of pallet wrapping techniques and learn how to optimize the stretch wrap process. Discover the importance of proper load configuration, determine the ideal film tension, and explore the different wrapping patterns to achieve maximum stability. From understanding the correct film application to troubleshooting common wrapping issues, we’ll provide you with all the knowledge you need to become a pallet wrapping maestro.

Join us on this journey to unlock the full potential of pallet wrappers and elevate your pallet wrapping game to new heights. Mastering stretch wrap machines will not only save you time and resources but also mitigate the risk of product damage during transit. Get ready to revolutionize your warehouse operations as we dive into the intricacies of pallet wrappers in this ultimate guide.

Understanding Pallet Wrappers: Types and Features

Pallet Wrappers come in various types and offer different features to ensure efficient and secure packaging of goods. Let’s explore the different types and features of these machines.

Automatic Pallet Wrappers: These machines are designed to automatically wrap pallets without manual intervention. They come equipped with advanced sensors and controls to measure and adjust the stretch film tension accurately. Automatic pallet wrappers are ideal for high-volume packaging operations, as they can wrap multiple pallets with consistent tension and speed.

Semi-Automatic Pallet Wrappers: As the name suggests, these machines require some manual assistance during the wrapping process. With semi-automatic pallet wrappers, the operator manually attaches the film to the pallet and initiates the wrapping cycle. Once started, the machine takes over, applying the stretch film and securing the load. These machines are versatile and suitable for medium to high-volume packaging needs.

Mobile Pallet Wrappers: Mobile pallet wrappers are designed for convenience and flexibility. These compact machines are mounted on wheels, allowing easy movement around the packaging area. They are often used in warehouses or distribution centers where pallet wrapping needs to be done at multiple locations. Mobile pallet wrappers provide the convenience of on-demand wrapping without the need for a dedicated wrapping station.

Features of Pallet Wrappers:

Stretch Film Carriage: The stretch film carriage is a crucial component of the pallet wrapper. It holds and dispenses the stretch film during the wrapping process. Pallet wrappers may feature different types of carriages, such as pre-stretch carriages that stretch the film before applying it to the pallet. This stretching process helps optimize the film usage and ensures secure load containment.

Control Panel: Pallet wrappers come equipped with control panels that allow operators to set various wrapping parameters. These parameters may include the number of wraps, film tension, wrap speed, and the ability to save custom wrapping programs. The control panel gives operators the flexibility to adjust the settings based on the specific requirements of the load being wrapped.

Safety Features: Pallet wrappers prioritize safety during operation. Some safety features commonly found on these machines include emergency stop buttons, safety barriers, and photoelectric sensors. These features help prevent accidents and protect operators and bystanders from potential injury.

Learn More

Understanding the different types and features of pallet wrappers is essential in selecting the right machine for your packaging needs. Whether you require fully automated operations, the flexibility of a mobile wrapper, or the versatility of a semi-automatic machine, there is a pallet wrapper available to meet your specific requirements.

Choosing the Right Stretch Wrap Machine for Your Needs

When it comes to selecting the perfect stretch wrap machine for your pallet wrapping needs, there are a few key factors to consider. Here are three important aspects to keep in mind:

Load Size and Weight: The first step in choosing the right stretch wrap machine is determining the size and weight of your loads. Machines come in various sizes and have different weight capacities. It’s crucial to select a machine that can comfortably handle the dimensions and weight of your pallets. By doing so, you ensure optimal performance and prevent any potential damage to your products during the wrapping process.

Film Compatibility: Another vital consideration when choosing a stretch wrap machine is the compatibility with different types of stretch film. Stretch films come in various thicknesses, strengths, and compositions. It’s important to ensure that the machine you choose can work efficiently with the specific type of film you intend to use. Factors such as film width, stretch ability, and pre-stretch options should be taken into account to guarantee a secure and effective wrap.

Machine Features and Automation: Lastly, take into consideration the features and level of automation that best suit your operational requirements. Some stretch wrap machines offer basic manual controls, while others provide advanced automation capabilities like adjustable wrap tension, film pre-stretch, and programmable wrapping patterns. Understanding your specific needs and production demands will help you determine the level of automation that is most beneficial for your packaging process.

By carefully evaluating load size and weight, film compatibility, and machine features and automation, you can confidently choose the right stretch wrap machine for your needs. Remember, selecting the appropriate machine will not only enhance your packaging efficiency but also contribute to the safe and secure transportation of your products.

Mastering the Art of Pallet Wrapping: Tips and Best Practices

When it comes to pallet wrapping, following a few tips and best practices can make all the difference in ensuring a secure and efficient load. Here are some key insights to help you master the art of pallet wrapping:

Optimal Preparations: Before starting the wrapping process, it is important to ensure that the pallet and the items being wrapped are properly prepared. Make sure the pallet is sturdy and in good condition, with no broken boards or weak spots. Additionally, arrange the items on the pallet in a stable manner, placing heavier and more durable goods at the bottom and lighter or fragile items on top.

Correct Film Tension: Achieving the right tension of the stretch film is crucial for maintaining load stability. Too little tension can result in loose and unstable loads, while excessive tension can cause product damage or film breakage. Aim for a balanced tension where the film is firmly stretched around the pallet but not overly tight.

Proper Wrapping Technique: Consistency and a systematic approach to wrapping are key. Start by anchoring the film to the pallet securely, ensuring it is taut. As you continue wrapping, overlap each layer by around 50% to create a strong bond between the layers. Pay attention to the corners and edges, ensuring they are well covered and protected. Finally, end the wrapping process by securing the film with a film clamp or by folding and tucking the loose end under the previous layers.

By following these tips and best practices, you can enhance the stability and integrity of pallet loads, minimize product damage, and improve overall operational efficiency. Mastering the art of pallet wrapping is not only about using the right equipment but also adopting a thoughtful and consistent approach to achieve optimal results.

Recent Comments